PRODUCT SERIES

CONTACT US

Add:Building 1, North District, Zhongke Innovation Industrial Park, Economic Zone, Weihai City

50 Axis 8-4096 Circle Mechanical Multi Circle

This product uses permanent magnets and magnetic induction elements. After magnetoelectric conversion, the angular displacement of the shaft is converted into an electrical pulse signal for output. It can be widely used in various automatic control and measurement fields, such as machinery manufacturing, shipbuilding, textile, printing, aviation, military industry, testing machines, elevators, etc.

Classification:

Key words:

Product Description

▋ ADK-economical absolute encoder

● Product description

Model:ADK-A50L8-A4096G4RCN

This product uses permanent magnets and magnetic induction elements. After magnetoelectric conversion, the angular displacement of the shaft is converted into an electrical pulse signal for output. It can be widely used in various automatic control and measurement fields, such as machinery manufacturing, shipbuilding, textile, printing, aviation, military industry, testing machines, elevators, etc.

This product has the characteristics of anti-vibration, corrosion resistance, pollution resistance, small size, low cost, high reliability, simple structure, etc. The internal use of ASIC devices, high reliability, long life, strong anti-interference performance, technical level is the domestic priority.

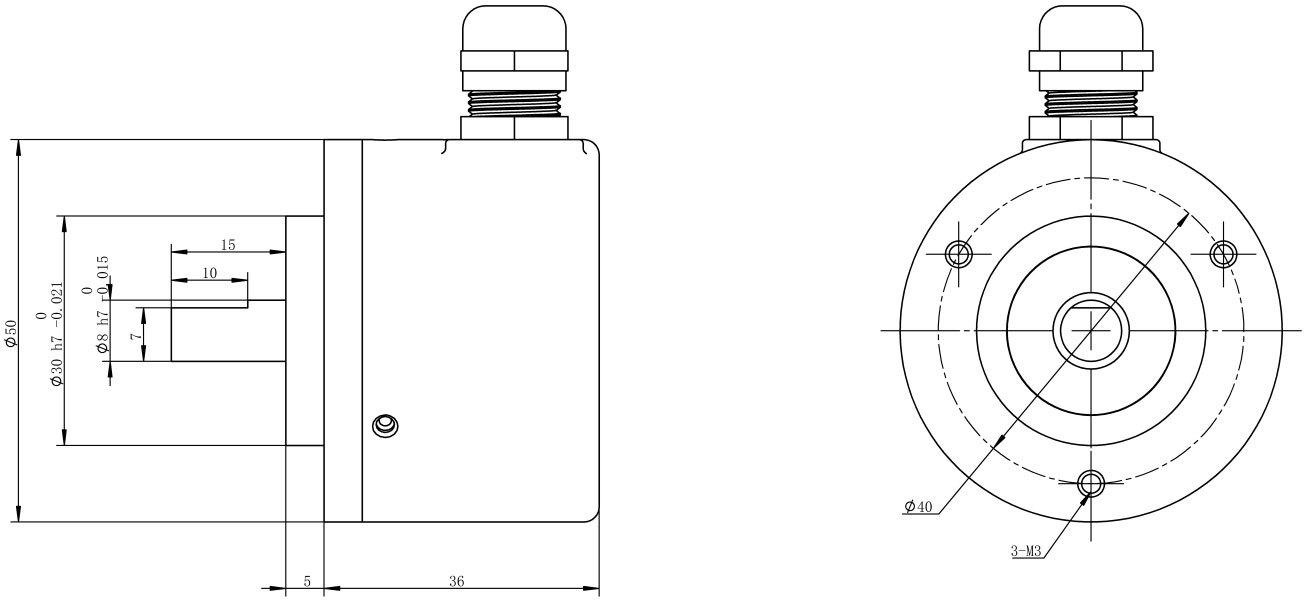

Model description: tighten the screw hole installation, the main body size is φ50mm, the axis is φ8, the cable is side-out, the resolution is 4096, the gray code negative logic is output in parallel, and the working voltage is DC8-29V.

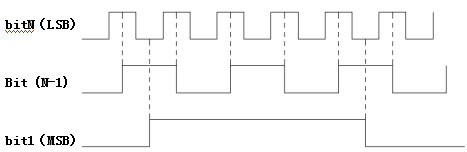

● Waveform

Note: The absolute parallel output encoder divides the circumference into corresponding equal intervals evenly according to the required accuracy, and each interval is represented by a code combination with a fixed signal of several bits, so that the encoder can still remember the absolute operation of the encoder after the power is turned off. position. If 1024 lines are required, a combination of ten signal lines is required, namely:

0: Gray code is 00000000000

1024: Gray code is 11000000000 (the above is positive logic, negative logic is the opposite)

▋ Technical Parameters

● Wiring table

| Lead color | Output signal (NPN collector output) |

| Red | Vcc |

| Black | GND |

| Shielded wire | Shielded wire |

| White | D0 |

| Gray | D1 |

| Yellow | D2 |

| Brown | D3 |

| Pink | D4 |

| Purple | D5 |

| Orange | D6 |

| Blue | D7 |

| Green | D8 |

| Light blue | D9 |

| Light green | D10 |

| Dark green | D11 |

☉ Note: The definition of encoder wiring is subject to the label on the housing

● Environmental parameters

| Operating temperature | -40~85℃ |

| Working humidity | 98% Max |

| Protection level | IP54 |

| Anti-magnetic interference | Common mode magnetic field suppression |

● Electrical parameters

| Resolution | 4096 |

| Operating Voltage | DC 8~29V |

| Working current | 500mA max |

| Output form | NPN open collector |

| Response frequency | 2MHz |

| Output current | 25mA Max |

● Mechanical parameters

| Starting torque (N·M) | 1.5x 10^(-3) |

| Moment of inertia (Kg·m²) | 9.0x 10^(-8) |

| Max shaft load | 200N (axial)/100N (radial) |

| Max speed r/min | 3000 |

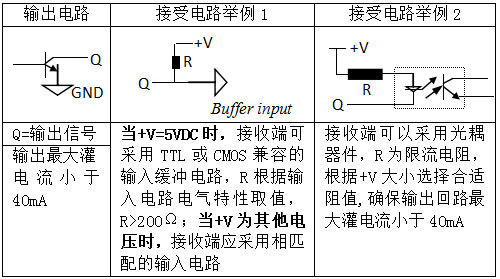

▋ Electrical parameters and output description

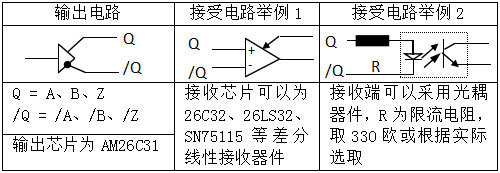

● Long line drive output

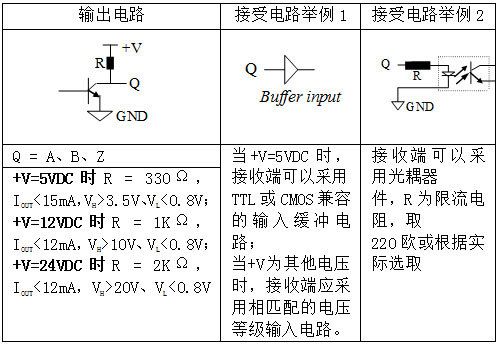

● Voltage output

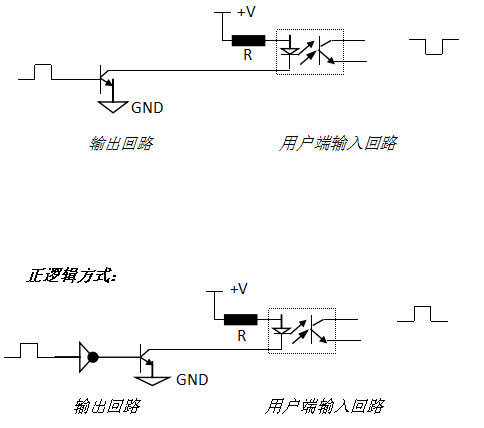

● Open collector output

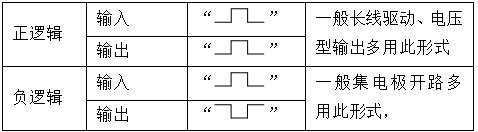

● Level logic

The encoder output logic includes two types: positive logic and negative logic:

☉ If the opposite logic is required, the signal can be inverted and counted by software or hardware at the receiving end, and the logic output form can also be specified when ordering.

● Output example

▋ Precautions

○ An elastic soft connection is adopted between the encoder shaft and the output shaft of the user end to avoid damage to the shaft system of the encoder due to the string movement and beating of the user shaft.

○ Please pay attention to the allowable shaft load when installing.

○ It should be ensured that the difference between the encoder shaft and the user's output shaft is less than 0.20mm, and the deflection angle to the axis is less than 1.5°.

○ Try to avoid knocks and hits during installation

○ Do not connect the power cord to the ground wire reversely.

○ The grounding wire should be as thick as possible, generally greater than φ3.

○ Do not overlap the output wires of the encoder to avoid damage to the output circuit.

○ Do not connect the signal wire of the encoder to a DC power supply or AC current to avoid damage to the output circuit.

○ The motor and other equipment connected to the encoder should be well grounded and free of static electricity.

○ Use shielded cables when wiring.

○ Before starting up, you should carefully check whether the product manual matches the encoder model and whether the wiring is correct.

○ For long-distance transmission, signal attenuation factors should be considered, and an output mode with low output impedance and strong anti-interference ability should be selected.

○ Avoid using in strong electromagnetic wave environment.

▋ Warranty conditions

Under the condition that the user abides by the component storage and use rules, within 12 months from the date of leaving the factory, the company will repair or replace it free of charge due to product quality problems. The specifications in catalogs, manuals or technical data are subject to change without notice.

● Mechanical Dimensions

THE COMPANY

Weihai idencoder electronic technology co.,ltd.

Idencoder is an technical enterprise Located in Weihai City ShanDong Province, China, have been providing Professional Encoder Solutions for hundreds of enterprises all over the world.

By the name of Weihai Idencoder Electronic Technology Co., Ltd, we have been specializing in developing, producing and marketing Industrial encoders. Our Main Products: A. Incremental Encoder; B. Programmable Incremental Encoder; C. Single-turn and multi-turn Absolute Encoder with Parallel, SSI, Modbus, Profibus, Canopen and Profinet interface; D. Draw Wire Encoder; E. Manual Pulse Generator

OUR SERVICE

To solve problems for customers, for marketing escort

Pre-sale service

According to the actual needs of customers to determine the equipment model and specifications, can also be customized according to the special requirements of customers, and provide customers with perfect solutions, really provide customers with a satisfactory and reasonable product. And can train relevant technical guidance for customers, so that they master certain technical knowledge and equipment maintenance skills.

Sales tracking

In the sales process, always track the process from production to delivery of customer orders, minimize the production and delivery cycle while ensuring product quality, and pay attention to product quality.

After-sales service

In view of customers' difficulties, we have specialized after-sales service personnel to solve customers' problems one on one until success, and responsible for providing customers with correct use skills to ensure the durability of the products in their hands.

PRODUCT MESSAGE