Understand where the servo encoder coupling should be changed in use

Release time:

2021-04-22 00:00

When choosing an encoder coupling, customers will consider its performance, service life, reliability, and whether there is noise. But there are still some unsatisfactory places in use, so where should the servo encoder coupling be changed in use?

The encoder coupling is an integrated metal elastic coupling. Suitable for couplings with small torque and zero rotation clearance. The production of encoder couplings has many advantages and high machining accuracy. Let's take a look at the areas where the encoder coupling needs to be improved.

1. The structure is complex and the machine adjustment and maintenance are difficult.

2. Low efficiency and slow moving speed reduce production efficiency. For fast and small encoder couplings, it is not as simple and flexible as a crank press.

3. Due to manufacturing, installation, load deformation and temperature changes, it is difficult to maintain strict and accurate alignment of the two axes after installation and adjustment.

The quality of the encoder coupling directly affects the working efficiency between the two shafts. For this reason, the structure has been improved, and a self-centering structure that can automatically center the rotor relative to the stator is designed. Some parts were redesigned and related experiments were carried out. The results show that the improved encoder coupling degree is greatly reduced, the main performance indicators are greatly optimized, the cost is reduced, and it has great promotion and application value.

What happens if the servo encoder coupling is broken?

If the encoder coupling is disconnected, the following results may occur:

1. The equipment cannot be rotated;

2. The measurement result of the encoder is not accurate.

3. The shaft offset of the coupling damages the encoder and causes the encoder to be scrapped;

Weihai Adike Electronic Technology is an encoder manufacturer with many years of history, specializing in the production of various types of CANopen absolute encoders, servo encoders, and industrial Ethernet encoders. The magnetic encoder developed and produced by Weihai encoder manufacturer is a cost-effective rotary encoder, its performance is not easily affected by dust and condensation; its structure is simple and compact, non-contact, long life, high and low temperature resistance, anti-vibration , Fast response, low cost, worth having! Find a manufacturer of magnetic encoders, or Weihai Adike.

Other News

Introduce the difference between Canopen bus and Canopen absolute encoder

Controller area network is one of the most widely used open field buses in the world. As a remote network communication control method with advanced technology, high reliability, complete functions and reasonable cost, CAN bus has been widely used in various automation control systems.

For example, the encoders inside printers and magnetic card machines have a simple structure, and many shells are not available. There is almost no need to talk about temperature, dustproof, waterproof, electromagnetic compatibility, and the price is extremely cheap.

What problems should be paid attention to when using CANopen absolute encoder

What problems should be paid attention to when using CANopen absolute encoder? CANopen absolute encoder is a device that converts changes in mechanical angle physical quantities into electrical signals.

How to use industrial Ethernet encoder to accurately measure speed

How to use industrial Ethernet encoder to accurately measure speed? In the use of encoders, angle or linear distance measurement is an important aspect, it can also be used for speed or linear velocity measurement. When the industrial Ethernet encoder rotates faster, the pulse frequency increases at the same rate.

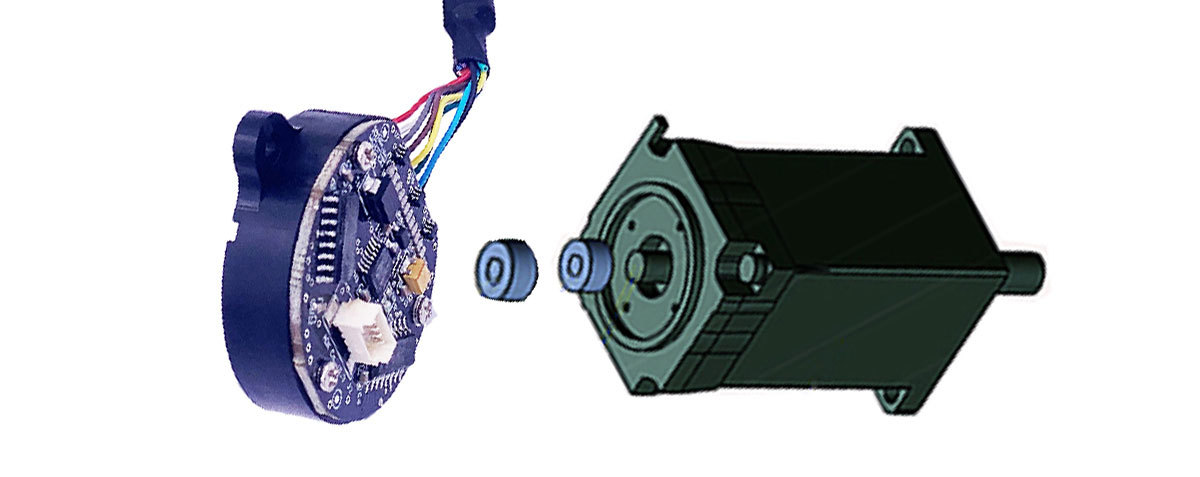

Briefly describe the installation process of the servo encoder

Servo encoder is a kind of sensor installed on the servo motor, used to measure the magnetic pole position and the rotation angle and speed of the servo motor.

Understand where the servo encoder coupling should be changed in use

When choosing an encoder coupling, customers will consider its performance, service life, reliability, and whether there is noise. But there are still some unsatisfactory places in use, so where should the servo encoder coupling be changed in use?